Acoustic loss at substantial ultrasonic strain

in

6Al-6V-2Sn and

sintered

6Al-4V titanium

David Wuchinich[1]

ă David

Wuchinich 2004

Keywords: Q, attenuation, dissipation, fatigue, titanium,

ultrasonic, sintered, powdered metal, stress

PACS code:

74.75.Ld

Abstract

The mechanical Q of the high

strength 6Al-6V-2Sn titanium alloy and of two alloys of sintered 6Al-4V is

measured and compared with values obtained for standard cast and rolled 6Al-4V

at 20 kHz cyclic strains ranging for 0.18 to 0.42 percent. 6-6-2 was found to exhibit comparable loss

to the standard samples while the sintered specimens revealed much lower

dissipation. Annealing of one of the

sintered samples reduced the Q to those found typical for cast and rolled

material. The 6-6-2 material survived

continuous operation at strains in the neighborhood of 0.4 percent. It appears that sintering may provide an

economical process for making ultrasonic horns and that intensities greater

than can typically be produced by use of 6-4 Ti may be available using 6-6-2Ti.

Introduction

Mechanical dissipation

resulting from hysteresis in the stress-stain relationship in many metals has

been studied extensively in relation to fatigue and the operational life of

components subjected to cyclic stress at ultrasonic frequencies because this

loss limits the maximum excursion that can reliably be produced[2]. As the alloy 6Al-4V titanium is used

extensively in ultrasonic welding and surgical horns, and is often subjected to

strains in the range of 0.25 percent during operation, Mason’s exemplary method

and comprehensive studies have provided a guide for fatigue -safe design for

this alloy[3].

A complete treatise of his methods has also been published[4]. Additional studies of similar alloys have

produced comparable results[5]: The mechanical Q is constant for strains up

to 0.25 percent, thereafter decreasing rapidly. In this respect, this alloy of titanium is distinguished among

other metals employed as horns, such as steel and aluminum, both of which exhibit

progressively greater loss with increasing strain[6]. A strain of 0.25 percent corresponds to a

stress of 276 Mpa (40 kpsi) and it is this value that has been adopted as the

practical endurance limit for titanium horns operating at ultrasonic frequencies.

Horns and ultrasonic

surgical tips have commonly been made by machining rolled stock taken from

castings. Recently, sintered versions

of the alloy have become available[7]

and offer substantial economies in the manufacture of large quantities of

identical items as the process results in horns having near to net finished

shape from molds. Sintering, however,

may result in porosity which, if occurring in regions subject to substantial

strain, can cause stress concentrations that precipitate failure. Hence, an acoustic evaluation of this

material’s tolerance of large strains is of interest.

Also of interest in this

study is the performance of the titanium alloy 6Al-6V-2Sn, known for having

higher strength than 6Al-4V and which has become available to users in common

rolled bar form in less than mill run quantities.

Theory

The half wavelength

resonator utilized by Mason and which closely resembles in action the classical

model of simple harmonic vibration utilizing two opposing and equal masses

connected by a mass-less spring is a simple candidate for evaluation of

acoustic loss. A schematic

representation of the structure is shown in Figure 1.

Figure 1 Test specimen geometry

This model is chosen for two

principal reasons: (1) stress is

confined to the spindle portion of the resonator and is substantially uniform

in this region and (2) the abrupt transistion in cross sectional area between

the mass and spring elements permit the production of large cyclic stress for

modest and easily produced free end amplitude excursions. As elastic loss is often a function of the

peak stress level, confinement and uniformity of stress permits a reliable

measurement of loss. Production of

stress levels likely to reveal substantial losses without resort to excitation

by high intensity transducer and horn amplifiers is also an advantage.

Exact and finite element

analysis reveal that indeed, for the first extensional resonant mode, the end

sections with the larger diameter move uniformly in opposite directions and

that the slender center section is subjected to substantially uniform strain

with a frequency approximately given by

(1)

(1)

with E representing

Young’s modulus.

The stored energy of

vibration, Es, can be computed as:

(2)

(2)

where s is the peak stress and V the volume. As the stress is principally located within

the slender stem of length l whose cross section, A, is constant, Eq.

(2) becomes:

.

(3)

.

(3)

V = Al, the

volume of the spindle. The exact value

can be computed from finite element modal analysis or from solutions for the

wave equation for a model consisting of connected and appropriately sized

prismatic steps[8] , but Eq.

(3) is sufficiently accurate for computations within fifteen percent of the

true value if the geometry is chosen so that the stress is predominantly

present in the stem.

The stress can be computed

from optical measurements of the displacement of the end mass using, for

example, a microscope with a calibrated reticule as:

![]() (4)

(4)

where d is the excursion (peak to peak motion of either end

mass) and l is the length of stem having a constant diameter.

Computation of the acoustic

loss at any given level of vibration can be made by measurement of the

temperature rise in the stem over a prescribed duration of vibration. The rate of heat generation in the spindle

can be written as:

![]() (5)

(5)

where Q is the actual

heat contained, Qm is the heat generated by mechanical loss and Ql

is the heat lost by conduction and radiation.

Measurement has shown that Ql

can be accurately represented as

![]() (6)

(6)

where K is the heat

loss coefficient and T is the difference between the spindle and

ambient temperature. K can be

found by measuring the fall in temperature once vibration ceases (dQm/dt

= 0). Since

![]()

with r the material density, C the specific heat

capacity and V the spindle volume, it follows that:

![]()

from

which

(7)

(7)

where

the temperature falls from T1 to T2 over an interval of time td.

Knowing

K, equation 5 may be integrated and solved for Qm:

(8)

(8)

Actual

measurement has shown that the rise in temperature during vibration is closely

proportional to the time so that T may be approximated as;

where

tb –ta is the interval of time over which

the temperature rises from Ta to Tb . Equation 8 can then be written as:

(8a)

(8a)

The energy dissipated per cycle of vibration, El,

is then

(9)

(9)

![]()

where ¦ is the

frequency of vibration

Q

is defined as the ratio of the energy stored to that lost per cycle multiplied

by 2p, and becomes, using the

expressions for Es given by equation 3 and El by equation 9 as:

(10)

(10)

Method

Two samples of sintered

6Al-4V titanium were obtained in the form of rough cylindrical blanks. Sample (#1) contained 10 percent titanium

carbide. The second sample (#2) had the

conventional formulation of the cast material.

. Figure 2 is a photograph of

the samples as received.

Figure 2 - Sintered sample

blanks as received

The extensional sound

velocity, c, was found from the sample dimensions and by measuring the

frequency of the first free-free flexural mode of vibration[9]

and the density obtained by measurement of displaced weight of water under

suspended immersion. Knowing both the

density and sound velocity permitted computation of Young’s modulus:

![]() (1)

(1)

where E is Young’s

modulus, r the density and c the

extensional sound velocity. For both

samples the density was found to be 4400 Kg/m3 (0.16 lbf/in3). The sound velocity for sample 1 was computed

from the flexural frequency to be 5100 m/s (200,000 in/s), while that for

sample 2 was 5300 m/s (210,000 in/s).

Hence the moduli:

Table 1

Density and Elastic

moduli for sintered samples

|

Sample |

Density, Kg/m3

(lbsf/in3) |

Modulus, GPa (Mpsi) |

|

1 (10 percent TiC) |

4400 (0.16) |

117 (17) |

|

2 (6-4) |

4400 (0.16) |

122 (18) |

To determine the mechanical

Q of these materials test specimens of Mason’s mass-spring-mass resonators[10],

also known as spool or dumb bell resonators, were machined from each. Figure 3 is a drawing of the powdered metal

specimens designed to resonate at 20 kHz.

Figure 3 – 20 kHz half

wavelength acoustic test specimen

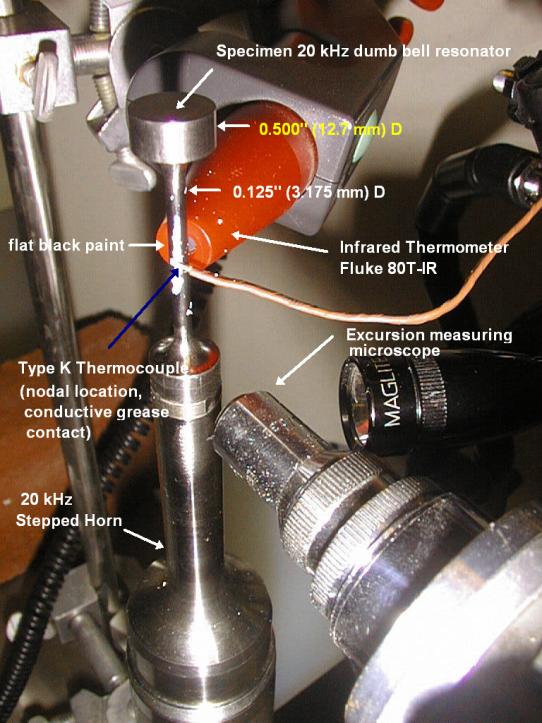

The specimens were attached

to a 20 kHz transducer driven stepped horn as shown in Figure 4 using a

cyanoacrylate adhesive. The temperature

rise in the center of the stem, which is a motional node, was made using a

non-contacting infrared thermometer and confirmed by measurement using a Type K

thermocouple. The test duration varied

with the level of applied vibration[DW1].

Results

Table 2 provides a

representative sample of the raw data.

The resonant frequency for all tests and both specimens was measured to

be 19,990 Hz. The temperature measurements

shown are averages of at least three separate runs.

Figure 4 - Testing apparatus

arrangement

Table 2

20 kHz Typical Thermal Measurement Data

|

Specimen |

d,

microns (.001in) |

Duration, s |

DTav

,oC (oF) |

Computed

stress[11],

MPa (kpsi) |

Strain

% |

Comment |

|

2 |

64 (2.5) |

10 |

8.33 (15.0) |

260 (37) |

0.21 |

|

|

2 |

76 (3.0) |

10 |

11.9 (21.5) |

310 (44) |

0.24 |

|

Figure 5 is a representative

oscilloscope trace of the spindle temperature rise and fall during a single

test.

Figure 5 - Spindle temperature

variation with time

Figure 6 plots the Q, computed

using the measured values of temperature rise and stress according to Eq. (6b),

versus the strain. The specific heat, C,

of titanium was taken as 565 J/oK/kg (0.135 BTU/lb/oF =

1260 in.lbs/lb0F). It is

noted that Q’s computed without correction for heat loss were only ten percent

larger than the values shown.

Figure

6

The

specimen containing 10 percent TiC fractured from repeated operation at 310 MPa

cyclic stress. The 6-4 specimen

fractured when testing was attempted at 450 MPa.

Similar

measurements were also made on a test specimen made of the alloy 6Al-6V-2Sn

which was first annealed for one hour at 700 C (1300 F), followed by air

cooling. The pertinent material

properties, again obtained by measurement of the flexural vibration frequency

and density are tabulated below.

Table

3

Density and Elastic

moduli for 6Al-6V-2Sn sample

|

Density, Kg/m3

(lbsf/in3) |

Modulus, GPa (Mpsi) |

|

4510 (0.163) |

99.3 (14.4) |

A plot

of the Q of this sample versus operating cyclic stress is provided in Figure 7.

Figure 7

Although

this material exhibits a substantially lower Q than either of the sintered

6Al-4V samples, it was also tested for endurance at 414 Mpa (60 kpsi) operating

cyclic stress with the spindle cooled by a water spray as shown in Figure

8. The sample survived repeated 6

million-cycle operation at this stress level.

Figure 8 – Endurance

test of 6-6-2 Ti alloy

Test specimens

were also made for two samples made from 6Al-4V round bar stock, revealing a Q

of approximately 5000 at strains up to 0.33 percent. Annealing of these samples did not affect the Q.

A sample

of the 6-4 sintered material was also annealed at 730 C for one hour and

allowed to air cool. A specimen made

from this sample was also tested.

Annealing reduced the Q from the values shown in Figure 6 to those found

for standard rolled round stock.

As a

check upon the thermal method applied here, samples of 6-6-2 and 6-4 specimens

were cemented to an identically resonant transducer-booster combination whose

quiescent power consumption at a measured vibration amplitude was known. The additional power consumed at the same

amplitude with the specimen attached is due to losses in the specimen and the Q

can be computed by dividing the energy of vibration by the power lost per

cycle. The results obtained agreed with

those listed here within ten percent.

Discussion

While the values of Q measured

here are substantially below those found by Mason 3, all alloys evaluated appear comparable or superior

in performance to the venerable 6Al-4V titanium alloy.

The Q of sintered 6Al-4V Ti

appears to be substantially greater than that measured for cast and rolled

material, and indicates that the material is a promising substitute for use in

highly stressed ultrasonic horns as its acoustic losses begin to mount at the

same stress threshold of approximately 275 Mpa (40 kpsi) exhibited by the

conventional product. The alloy

containing 10 percent Titanium carbide and recommended for its ease in

machining, while exhibiting more modest performance and progressive degradation

at substantially lower dynamic stress, appears worthy of evaluation for use in

applications where the maximum dynamic stress does not exceed 200 Mpa (30

kpsi).

The 6-6-2 alloy exhibits about

the same losses as that shown in the samples made of common rolled 6-4 but it

appears capable of sustaining cyclic strains in the neighborhood of 0.4 percent

at 20 kHz in applications where cooling can be provided.

Acknowledgements

The author thanks Stanley

Abkowitz of Dynamet Technology for discussion of sintered products’ properties

and for supplying the samples and Professor Daniel Bershers of Columbia

University for advice regarding his own and W.P. Mason’s dynamic strain studies.

, where f’' is the resonant frequency with mass

, where f’' is the resonant frequency with mass